How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser right into Fibre production processes represents a significant advancement in quality assurance approaches. By using real-time, accurate dimensions of Fibre diameters, this modern technology deals with the crucial demand for uniformity in production criteria. With its capacity to swiftly identify discrepancies and punctual corrective steps, the analyser not just enhances product dependability but also contributes to total functional performance. As industries increasingly focus on quality and compliance, recognizing the complete impact of such technologies ends up being important. What effects could this have for the future of Fibre production?

Value of Fibre Diameter Measurement

Exact dimension of Fibre Diameter is vital in the area of optical Fibre modern technology, as it straight influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and general transmission efficiency. Precision in determining Fibre Diameter makes certain that the optical properties are maintained within defined resistances, which is essential for optimal signal honesty.

Variations in Fibre Diameter can lead to increased losses because of spreading and modal dispersion, impacting the top quality of data transmission. In high-speed interaction systems, such disparities can result in considerable deterioration of signal quality, causing data errors and minimized efficiency. Moreover, constant Fibre Diameter is crucial for compatibility with adapters and splicing technologies, which are integral components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily count on accurate Diameter measurements to make sure conformity with industry requirements. By executing robust dimension methods, producers can boost product reliability, lessen waste, and improve general system efficiency. Hence, the importance of Fibre Diameter measurement can not be overemphasized, as it serves as a cornerstone in the development of optical Fibre innovation and its applications in modern-day interaction networks.

How the Analyser Works

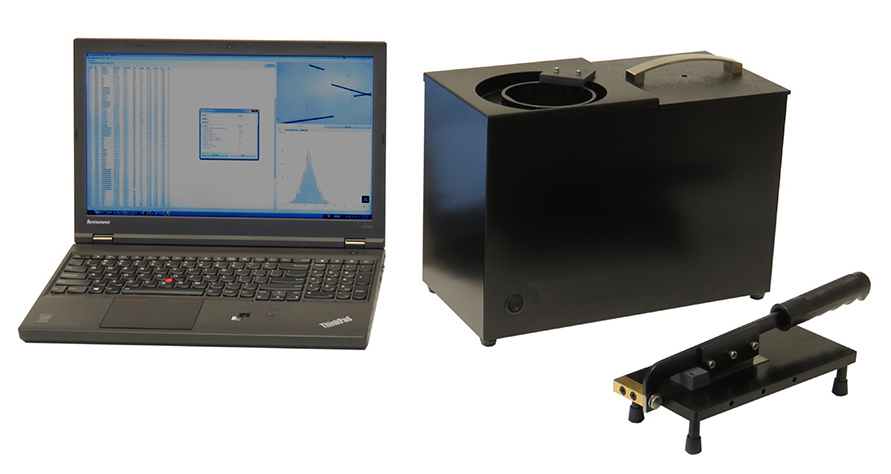

The reliable dimension of Fibre Diameter depends on sophisticated analytical techniques that make certain accuracy and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser technology and progressed image processing algorithms to accurately evaluate the Diameter of fibers as they are created

Initially, a laser beam of light is routed at the moving Fibre, producing a cross-sectional shadow. The analyser captures this shadow making use of high-resolution cameras placed purposefully along the assembly line. The recorded photos are then processed in real-time to figure out the Fibre's Diameter with phenomenal precision.

The system utilizes sophisticated formulas that represent various factors, consisting of variations in light intensity and ecological problems, to boost measurement integrity. It can identify minute adjustments in Diameter, such as changes that could take place throughout the manufacturing procedure.

Moreover, the analyser can taking care of multiple fibers at the same time, raising throughput without compromising precision. By giving instantaneous comments on the Diameter, the Optical Fibre Diameter Analyser plays a critical role in maintaining stringent quality assurance standards, guaranteeing that the end product satisfies industry specs and customer demands.

Benefits of Real-Time Monitoring

While typical techniques of monitoring Fibre Diameter frequently involve lengthy post-production checks, real-time monitoring considerably boosts the performance and top quality of optical Fibre production. optical fibre diameter analyser. This proactive approach enables suppliers to recognize deviations in Fibre Diameter as they take place, instead than waiting until production is total to evaluate high quality

By continually measuring the Diameter throughout manufacturing, manufacturers can ensure that the fibres satisfy rigid specs, resulting in minimized irregularity and enhanced consistency. Real-time monitoring additionally enables prompt corrective activities to be taken, reducing waste and preventing defective fibres from getting in the supply chain.

Furthermore, this technology promotes boosted information collection and analysis, offering understandings into manufacturing trends and potential locations for improvement. Such data-driven decision-making equips producers to additional reading maximize processes and keep high standards of top quality control.

Furthermore, real-time surveillance cultivates a society of continual improvement within the manufacturing atmosphere. Workers are a lot more engaged when they can see the impact of their operate in real-time, causing enhanced accountability and a dedication to quality. On the whole, the implementation of real-time monitoring systems in optical Fibre manufacturing converts to remarkable item high quality and enhanced consumer contentment.

Effect On Production Efficiency

Executing optical Fibre Diameter analysers significantly enhances production efficiency by streamlining the production procedure. These devices help with continuous monitoring of Fibre Diameter, permitting manufacturers to find discrepancies in real-time. By identifying disparities immediately, assembly line can be adjusted rapidly, decreasing downtime and decreasing the chance of producing faulty items.

Furthermore, the combination of these analysers into the manufacturing process makes it possible for much better source allowance. With exact Diameter dimensions, operators can maximize material usage, making certain that resources are not thrown away on mistaken fibers. This accuracy also contributes to less revamp and junk, ultimately reducing manufacturing prices.

The automation given by optical Fibre Diameter analysers reduces reliance on hand-operated evaluations, which are typically lengthy and susceptible to human error. Consequently, staff members can focus on more critical tasks, improving general efficiency.

Furthermore, the data produced from these analysers can notify process enhancements and assist in far better decision-making. By examining patterns in Fibre Diameter variants, suppliers can execute proactive measures to enhance production techniques and keep regular quality. In recap, optical Fibre Diameter analysers play an essential role in increasing production effectiveness, bring about higher quality outcome and enhanced success.

Study and Success Stories

Across different markets, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One prominent instance is a leading telecoms firm that faced challenges with irregular Fibre diameters, causing boosted denial prices. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, leading to a 30% reduction in issues and substantial expense savings.

In addition, a research study institution concentrating on advanced products utilized optical Fibre Diameter analysers to refine their speculative processes. The analyser's capacity to provide thorough insights right into Fibre consistency made it possible for the advancement of cutting-edge materials with enhanced performance attributes.

These success tales underscore the necessary duty of optical Fibre Diameter analysers in boosting quality control, enhancing manufacturing efficiency, and driving technology across diverse sectors.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality control within Fibre manufacturing. As shown via numerous instance researches, the analyser confirms crucial for attaining premium item top quality in Fibre production.

The implementation of optical Fibre Diameter analysers enabled for rigid quality control, making certain that the created fibers met exacting industry standards.In verdict, the Optical Fibre Diameter Analyser plays a critical duty in enhancing quality control within Fibre manufacturing.